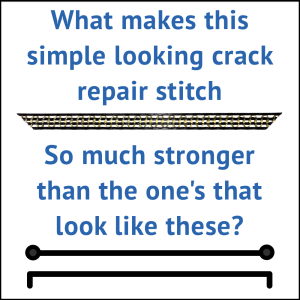

Why the Grid Stitch Outperforms the Competition

At first glance, a stitch or staple with ends on it might appear to be a stronger solution for crack repair that our flat Grid Stitch. In fact, our first crack repair product had ends on it like several others on the market today–but then we discovered a better method based on our ICC Certified InvisiBeam wall reinforcement system technology.

At first glance, a stitch or staple with ends on it might appear to be a stronger solution for crack repair that our flat Grid Stitch. In fact, our first crack repair product had ends on it like several others on the market today–but then we discovered a better method based on our ICC Certified InvisiBeam wall reinforcement system technology.

To fully appreciate how much stronger the Grid Stitch is when compared to other products, we first have to understand how Epoxy works. Epoxy forms a chemical bond with concrete that can be compared to a weld. For example, the Xtreme 4000 Epoxy that we include with the Grid Stitches has a pull off strength of approximately 5,000lbs. Concrete alone breaks with as little as a few hundred pounds of tension.

For Carbon Fiber to fully adhere to Concrete with Epoxy, it needs to be fully saturated–something that does not happen with a flat surface stitch like you see in all other crack repair products. This allows the carbon to easily delaminate and forces all of the load to the ends of those stitches. Those little ends become the only mechanical bond, and they are by far the weakest point of the the stitch or staple.

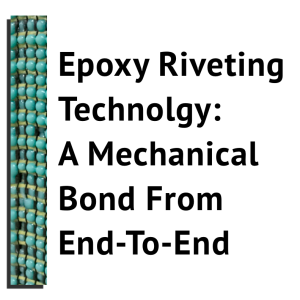

The Grid Stitch, on the other hand, has two very distinct advantages: First, the carbon fiber is pre-cured in our factory with Epoxy, meaning saturation is not an issue. Second, it’s open grid design allows the epoxy to flow throughout the entirety of the stitch. This creates epoxy “rivets” through the entire surface area of the stitch, which means its fully mechanically bonded to the crack from end to end.

This innovation not only earned us a patent, but has been tested time and again to outperform competitive products.

Don’t let looks deceive you, look at the science and Switch to the Stitch!

Grid Stitch Taken to Failure at over 6200lbs

Competitive Stitch Taken to Failure at ≈ 1,500lbs