Case Studies

Basement Corner Repair

Shortly after purchasing this New Jersey home, the new owner discovered significant foundation problems that were not discovered in the home inspection. The most significant was a serious failure to…

Read MoreMilwaukee Double T Parking Garage

The parking garage at the Tosa Center Medical Clinic experienced failed welds of the 3.5″ JVI flanges, which is a common occurrence in Double T structures. The 10ft spans had…

Read MoreInvisiBeam Blocking Out

On a non-load bearing wall in which the floor joists are running parallel to the wall being reinforced, it’s important to block out so that the load can be transferred…

Read MoreTop Anchor for Concrete Porch Cap Installation

The Fortress InvisiBeam system was chosen to reinforce this cracking and bowing wall in Lafayette, Indiana. The challenge was a drop ceiling with a concrete slab. This type of ceiling…

Read MoreVirginia Box Culvert

A new precast box culvert bridge was set in place to replace an old bridge beyond repair. The Virginia Department of Transportation has utilized Fortress Kevlar® for over ten years…

Read MoreFortress Kevlar® Utilized on Iconic Roosevelt Bridge

The Roosevelt Bridge in Stuart Florida is a segmental bridge and an icon of the south Flordia community. In 2020 reports came in that concrete was falling into the St.…

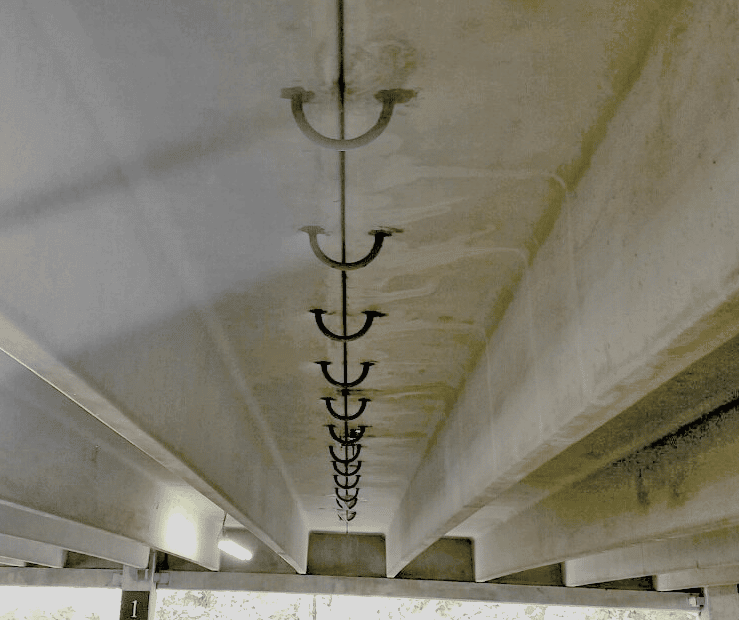

Read MoreHotel Parking Garage

Failure of steal and welds due to corrosion, tension, and shear stress required seam maintenance of the Double Tee parking garage. Double Tee “hotshot” Anchors were utilized to reinforce the…

Read MoreBasement Wall Corner Brace

This interior block basement wall was cracking in deflecting in over an inch in the corner. The wall was prepped, brace locations were marked, then crack was filled with Xtreme…

Read MoreRetail Center Slab Crack Repair

This large retail center was experiencing severe cracking in multiple areas. The contractor installed approximately 1,000 Crack Stitches as part of the overall space remodel. As the images show, stitches…

Read MoreResidential Block Wall Shear

This hillside home was being completely renovated when it was discovered that three different walls were experiencing significant inward deflection. One wall was also suffering from 1-1.5″ of bottom shear.…

Read More